Environmental Impact of Pressure Washing vs. Replacing Block Paving/Flagging

Both pressure washing and replacing block paving or flagging have their environmental pros and cons, often stemming from water use, pollution, and material sustainability. Here’s a look at both options to understand their environmental impact and to help decide which is the greener choice.

1. Understanding Pressure Washing and Its Environmental Impact

Pressure washing, or power washing, is a cleaning process that uses high-pressure water to remove dirt, algae, and other debris from surfaces like block paving, driveways, and sidewalks. While highly effective, the environmental footprint of pressure washing includes water usage, runoff pollution, and energy consumption.

Key Environmental Considerations in Pressure Washing

Water Usage: Pressure washing consumes a substantial amount of water. A typical pressure washer uses about 2-5 gallons of water per minute, which can quickly add up, especially for large paved areas. For instance, cleaning a 500-square-foot driveway could require hundreds of gallons of water, depending on the duration and intensity of cleaning.

Pollutants in Runoff: Pressure washing can lead to harmful runoff containing detergents, oils, and other contaminants from the surface. If untreated, this runoff often enters storm drains and eventually reaches local water systems, potentially harming aquatic life. Using environmentally friendly detergents or even just water alone can help minimize the risk, but pollutants like oil and dirt still risk being washed into ecosystems.

Energy Consumption: Electric or gas-powered pressure washers consume energy, and gas models especially can produce carbon emissions. Although small in comparison to larger machines, these emissions contribute to the carbon footprint of pressure washing.

Ways to Mitigate the Environmental Impact of Pressure Washing

Water-Efficient Equipment: Opt for water-efficient pressure washers that minimize water consumption.

Biodegradable Detergents: Using eco-friendly cleaning agents can reduce the environmental impact on local ecosystems.

Containment Measures: Employing barriers to contain runoff can prevent harmful chemicals from entering storm drains.

2. Environmental Impact of Replacing Block Paving/Flagging

When block paving or flagging reaches a state where it’s no longer functional or aesthetically pleasing, property owners might opt for replacement. This process involves removing old materials and installing new ones, which often includes the manufacturing, transportation, and disposal of paving materials.

Key Environmental Considerations in Replacing Paving/Flagging

Resource Consumption: Creating new pavers or flags often involves energy-intensive processes. The extraction of raw materials, such as sand, gravel, and clay, along with the manufacturing of concrete or natural stone products, has a significant environmental impact, generating carbon emissions and contributing to resource depletion.

Waste Generation: Replacing existing paving generates waste, especially if the old pavers or flags are discarded. While some materials, like certain types of concrete or stone, can be recycled, this requires additional energy and processing. Waste disposal also often involves transporting materials to landfills, contributing further to emissions.

Transportation Impact: The transportation of new materials from production facilities to the installation site adds to the carbon footprint, with large trucks and heavy machinery often involved. In many cases, older pavers can be heavy and difficult to transport for recycling, leading to further emissions.

Disturbance to Soil and Local Ecosystems: Excavating and replacing paving surfaces disrupts soil ecosystems and can lead to erosion or changes in local drainage patterns. This may have downstream effects, such as water pooling, changes in soil composition, and impacts on nearby plants or wildlife habitats.

Sustainable Approaches to Replacement

Recycled Materials: Opting for recycled or reclaimed materials can reduce the environmental impact, as these avoid the need for new raw materials.

Local Sourcing: Sourcing materials locally can significantly reduce the transportation emissions associated with long-distance hauling.

Modular Replacement: Replacing only damaged sections instead of a full reinstallation can also reduce waste and material usage.

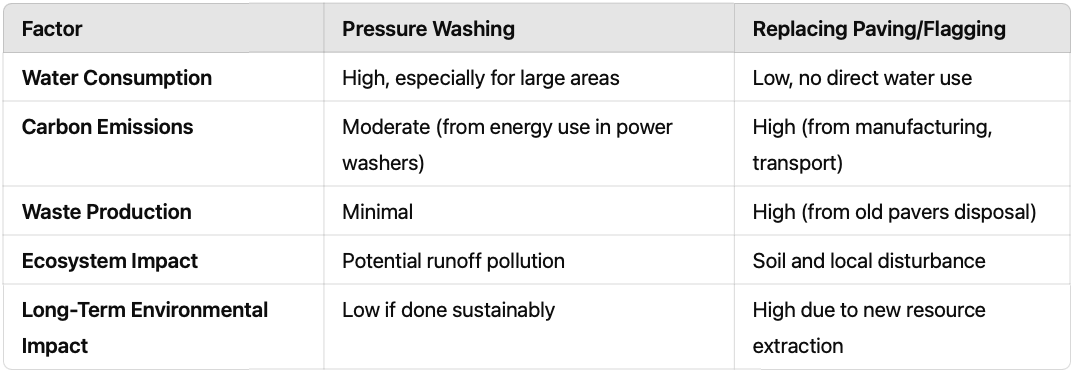

3. Comparing Environmental Impact: Pressure Washing vs. Replacement

Conclusion: Which is Greener?

Pressure washing is typically the more environmentally friendly choice when compared to a full replacement of block paving or flagging. While pressure washing does have water and energy considerations, the impact of producing, transporting, and disposing of paving materials for a full replacement generally results in a higher environmental cost.

To make pressure washing even more sustainable:

Use water-efficient equipment and biodegradable detergents.

Implement runoff control measures to protect local waterways.

However, if paving must be replaced due to severe damage, choosing eco-friendly options such as reclaimed or recycled materials, sourcing locally, and reducing transport distances can help mitigate the environmental impact.

In essence, pressure washing is a greener choice for maintaining paving surfaces when they are in good condition, while thoughtful replacement practices are key when reinstallation becomes necessary.